Who We Are

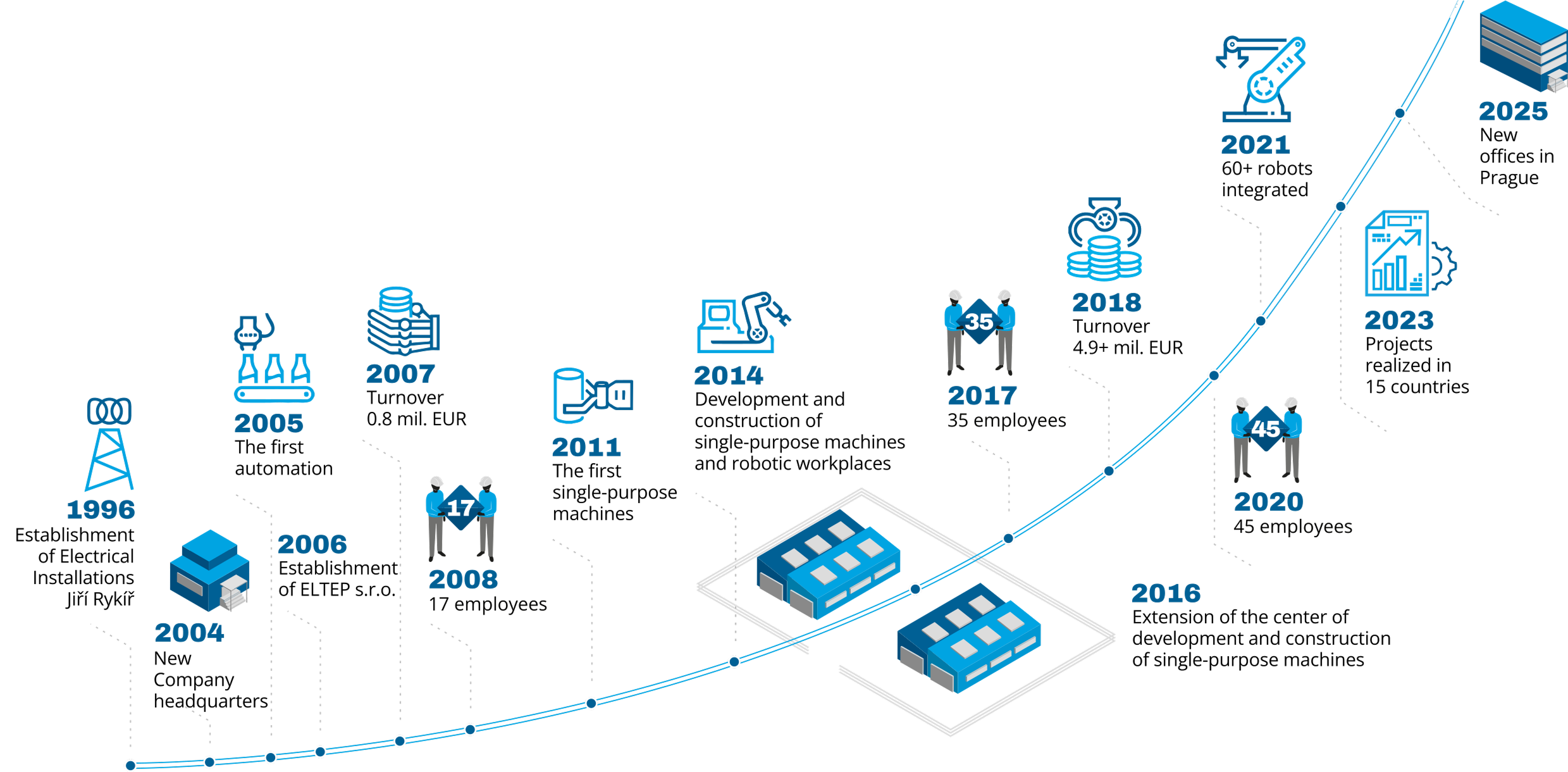

We have been industry integrator since 2006. During that time, we have transformed from a small family business into a company whose stability is backed up not only by its growth, but mainly by many satisfied local and foreign customers. At the same time, we approach each client individually and their satisfaction is crucial for us.

The alpha and omega of our work is industrial automation, process control, robotics and complex development of single-purpose machines. The current focus is the implementation of Industry 4.0 principles, such as digitization of production, data visualization etc.

Our team of professionals applies the many years of experience they have gained through training and hard work to provide you with a unique product to suit your specific needs. We work on a ‘turnkey’ principle, delivered to you by our expert team of specialists following the requirements of continual industry development.

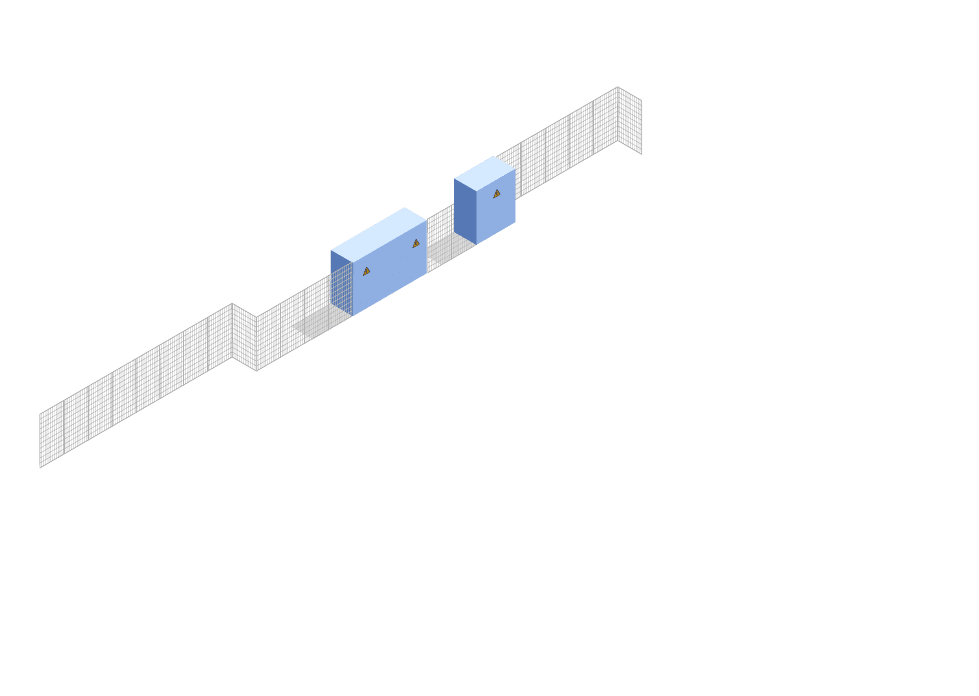

Industrial

Units

Our main purpose is to understand our client’s needs and to answer them quickly and professionally. We offer reliable cooperation and 360 degree service to our clients who require comprehensive services in terms of design and execution of work. As of implementation, we provide a complete service and the supplies from electrical installation to the implementation of control and visualization systems. All our solutions meet the most demanding legislative and production standards in the automotive and general industry sectors.

Painting

Measurement and Control

Energy Monitoring

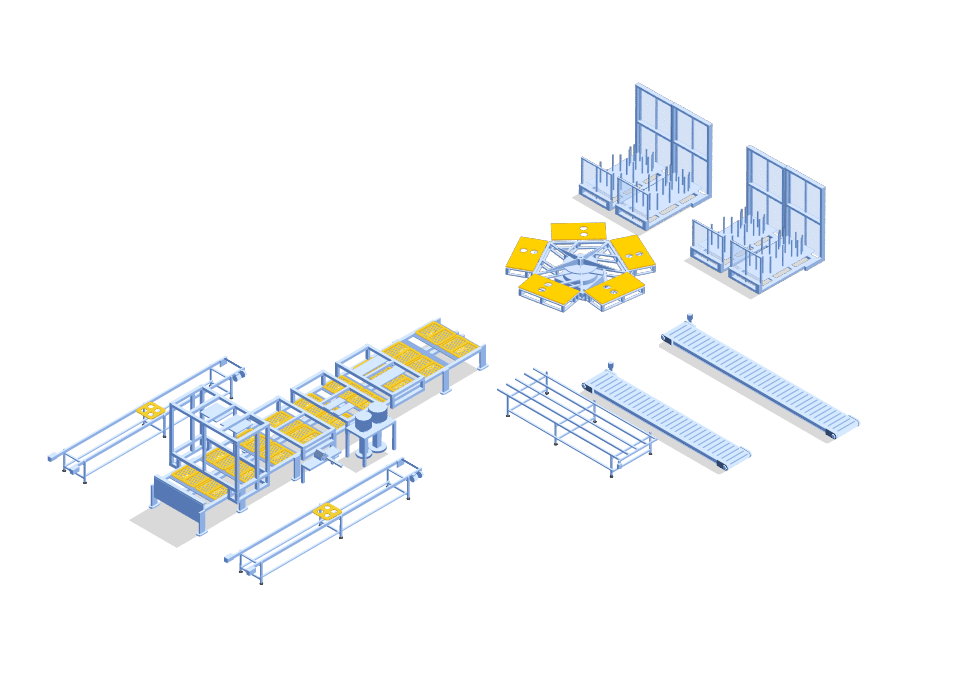

Material Conveying

Central Management

Power Supply System

Single-Purpose

Machines

If you have not yet found a single-purpose machine that would solve your needs, do not despair! Thanks to our experience, original approach and modern technologies, we can automate almost anything. We will not stop at any requirement; but rather any is a new challenge for us!

Let our technicians map out your requirements and our developers will take care of the rest.

We have a strong background covering all needs for the development and construction of equipment that must meet the most stringent requirements for safety, quality and reliability.

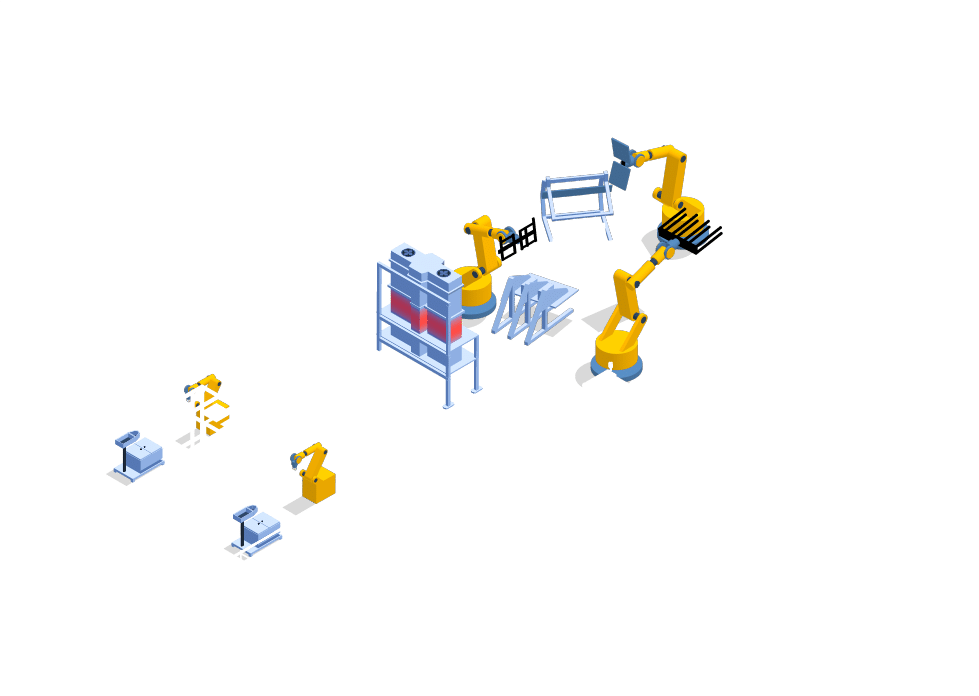

Robotic Workplaces

Testers

Single-Purpose Machines

Vision Systems and Bin Picking

Assembly Lines

Palletization

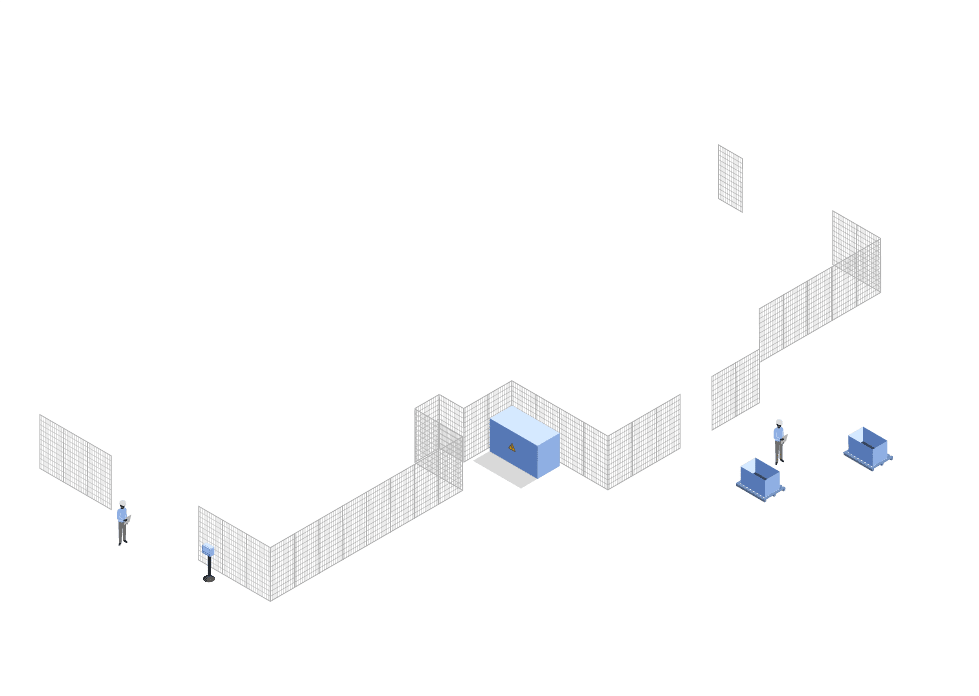

Service

24/7

Our complex solutions are always under control, which allows us to react to unexpected situations and resolve them quickly, even in live operation.

Services we offer do not stop with the successful implementation and handover of our solution. We also provide a high level of after sales care. We, as a professional company, take the satisfaction of our customers very seriously and for this reason we offer a wide range of after sales services including a 24/7 service line.

Hotline 24/7

Service Team

Spare Parts

Simulation SW

ELSIDO

Based on many years of experience managing paint lines, our company has developed simulation software for designing and verifying conveyor lines. The software can simulate real-line behavior while analyzing and validating the line’s set parameters based on your requirements, process, and subtests. After evaluating the input data, the software identifies potential problem areas and recommends solutions.

Takt Time

Dimensions of Jigs and Trolleys

Speed of Conveyors

Other Technological Elements

Cobots

A collaborative robot is designed for cooperation with people and its main advantages are safety, flexibility and speed of integration into a production.

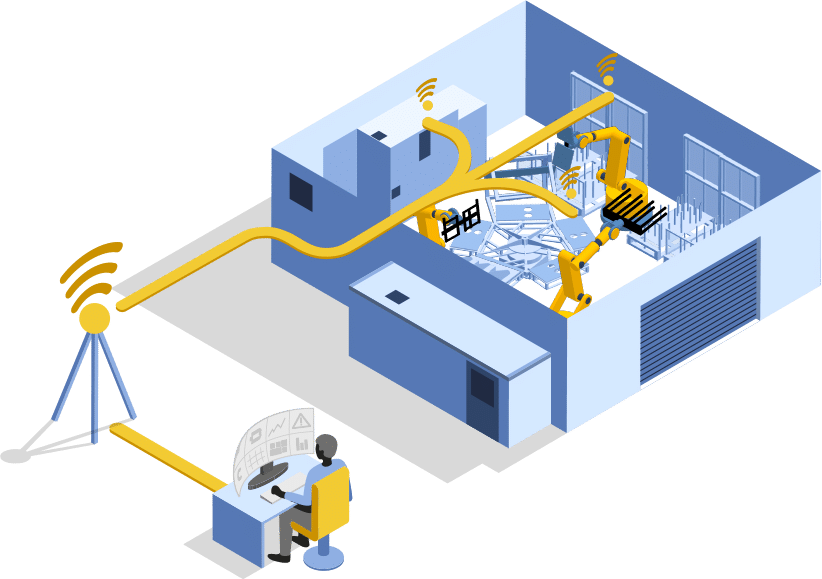

Industry 4.0

Modern production management increases competitiveness. Digitization of production, connection to the cloud and increasing the share of automation are challenges for the coming years.

Chose Us

Chose Us

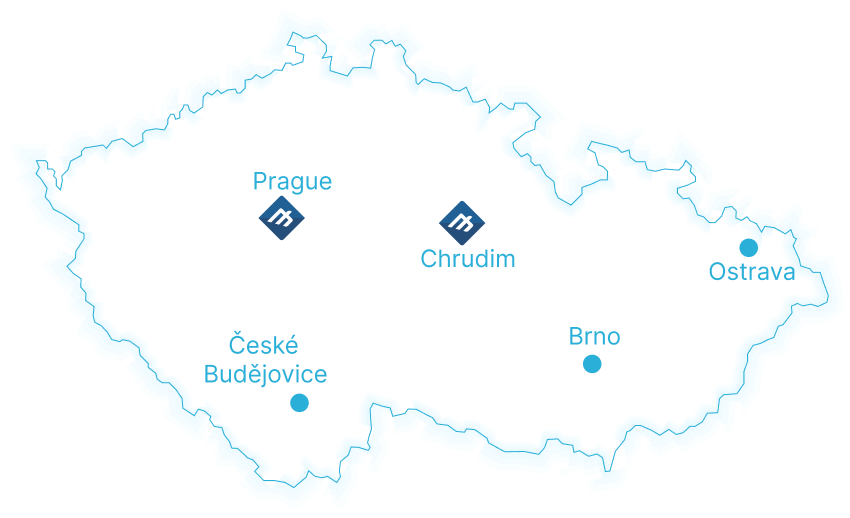

Where to Find Us